GENERATIONAL CRAFTMANSHIP

THE CRAFT

Our group of artisans is a family community that has passed their trade on from generation to generation. They all carry the mindset of a craftsperson—the obsession to detail, the passion, and the ingenuity that goes into making something by hand. Their level of skill is beyond what you would find in a large manufacturing setting. They take so much pride in the quality, details, and the process.

All of our artisans are trained to do every piece of production to keep their skills sharp, but each individual naturally excels in one area or another.

STEP 1: LEATHER

We ensure our leather is coming from the most sustainable source possible. Sapahn’s hides are by-products of the meat industry. If the hides weren’t being used by our tannery partner, they would just be thrown away. And while we know animal-based leather can be a divisive topic, we feel that turning a product that would otherwise be waste into something beautiful, that lasts a lifetime, is worthy. And there is no denying that leather is such a durable material, which means it will endure many years of wear instead of ending up in landfill like many cheaper alternatives do.

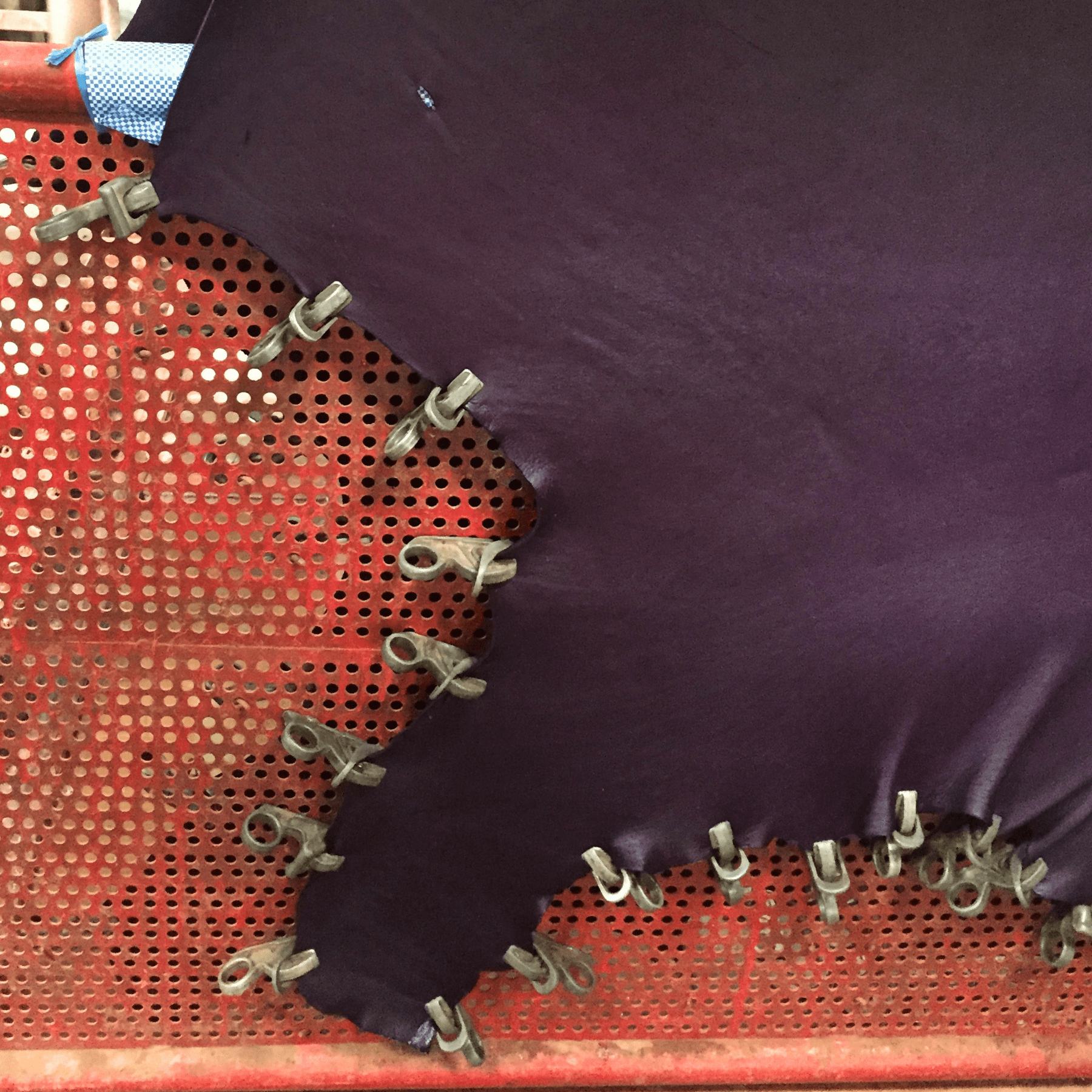

STEP 2: TANNERY

All of our leather is hand-processed and -dyed in small batches by a 3rd-generation family owned and run tannery. Over the last few years we have built up enough trust with them to be allowed access to see their process first-hand. By doing this we have also been able to start working with them on steps to make their business more environmentally friendly. For example, although they have a water purifier to filter the waste water they produce from the tanning process we realized it wasn’t the best one for the job. Sapahn is now working with them to identify and install a better water purification system.

STEP 3: DESIGN

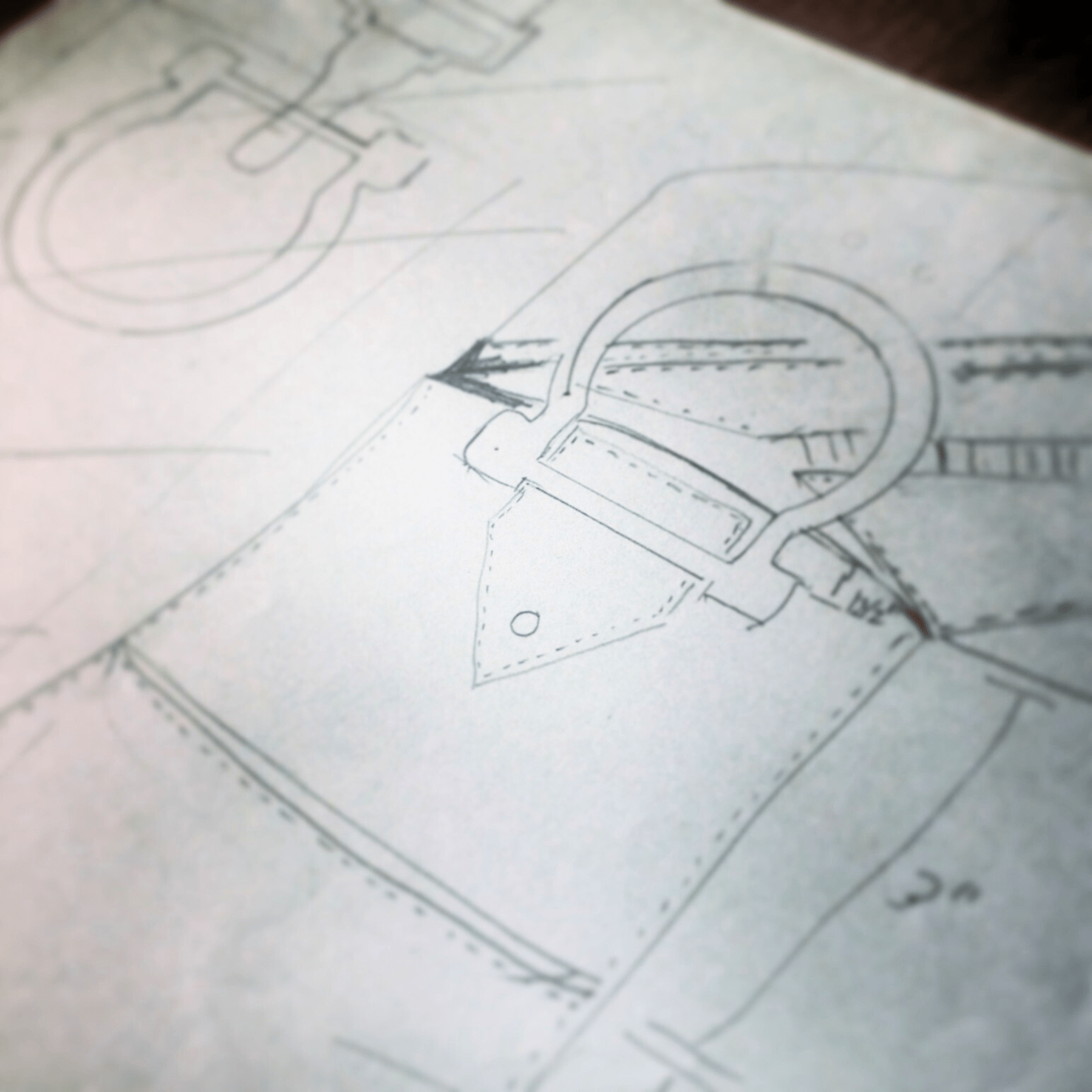

Our founder and designer, Brooke, starts each design season by looking at what our customers have been asking for and reflecting on lifestyle needs and forecasted trends. Brooke sketches up her new designs and modifications to existing Sapahn styles.

Once Brooke has worked up a sketch she’ll take it to our head artisans to discuss construction details. In a session of beautiful collaboration, they add in their ideas and then take the design back to the village where all the other artisans give their input on the new design. Here at Sapahn we pride ourselves on our handmade process so it’s important to us that the people making the products have their voices heard. We want them to love what they’re making because this isn’t a production line, this is a craft, an art.

STEP 4: PATTERN MAKING

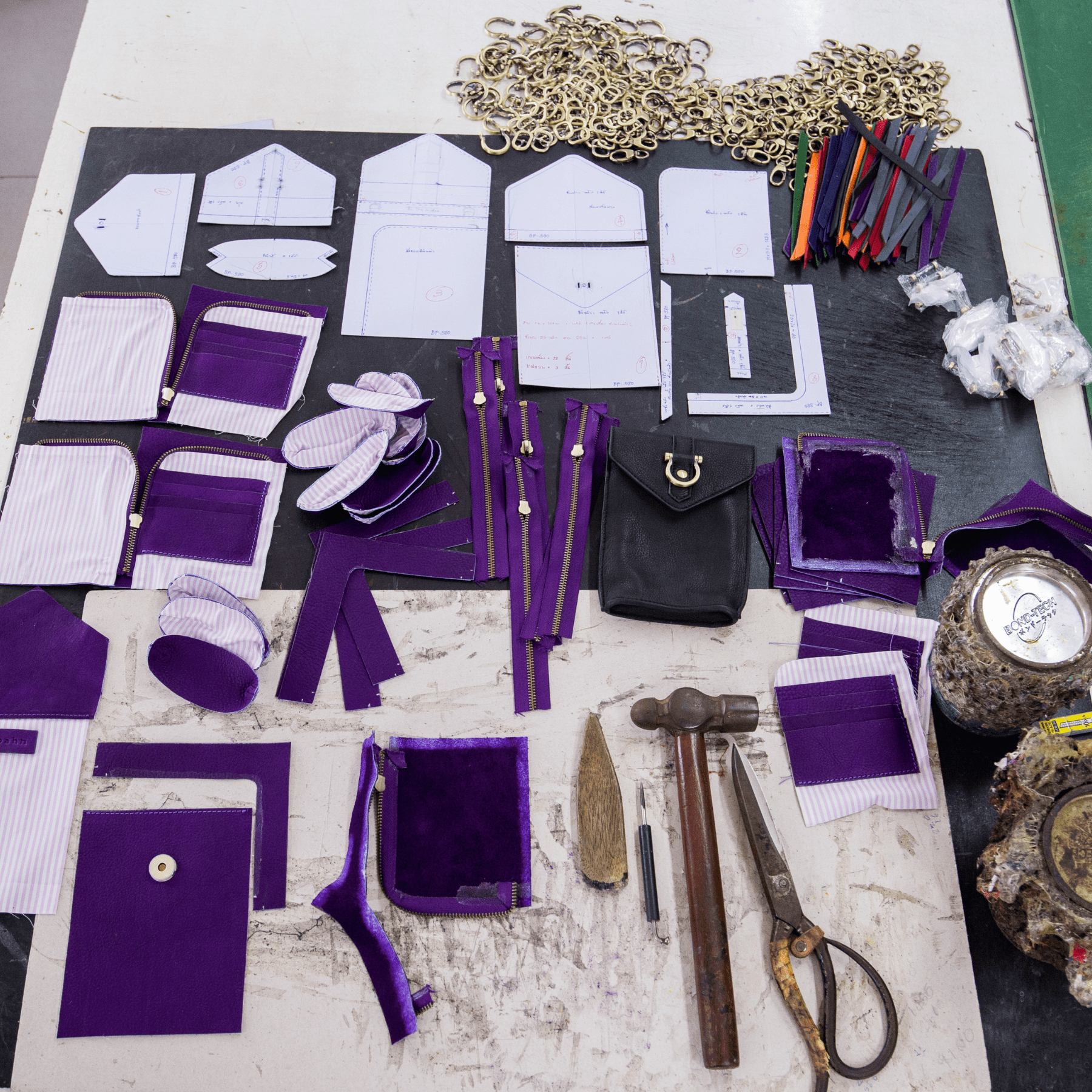

After the design is completed on paper, our artisans make the pattern the old fashioned way with rulers, pencils, and card stock paper. This is a skill that takes years to perfect. We are lucky to have three artisans who have mastered this skill and are able to take our idea to reality. The artisans create a sample bag to ‘test drive’. Based on the sample bag we decide on things like zipper size, strap length, and pocket size. When all those details are ironed out the leather for each bag is traced by hand and cut to the right shape and size.

At this point we also ensure that we create as little waste as possible by using scraps when and where possible. We’re a bit like hoarders in that way, we’ll keep just about everything until we really can’t use it anymore. At that point we donate any leftover pieces of leather to the art students at the local university who use the leather in their projects.

STEP 5: STITCHING

Once each piece of leather is cut into the right shape the bag goes to the sewing machine. Smaller pieces such as bag straps and handles are completed first. Each of the artisans is trained in every part of the stitching process – that means one bag is being made by the same person from start to finish ensuring top-notch quality and attention to detail. We think that’s pretty amazing!

STEP 6: LINING

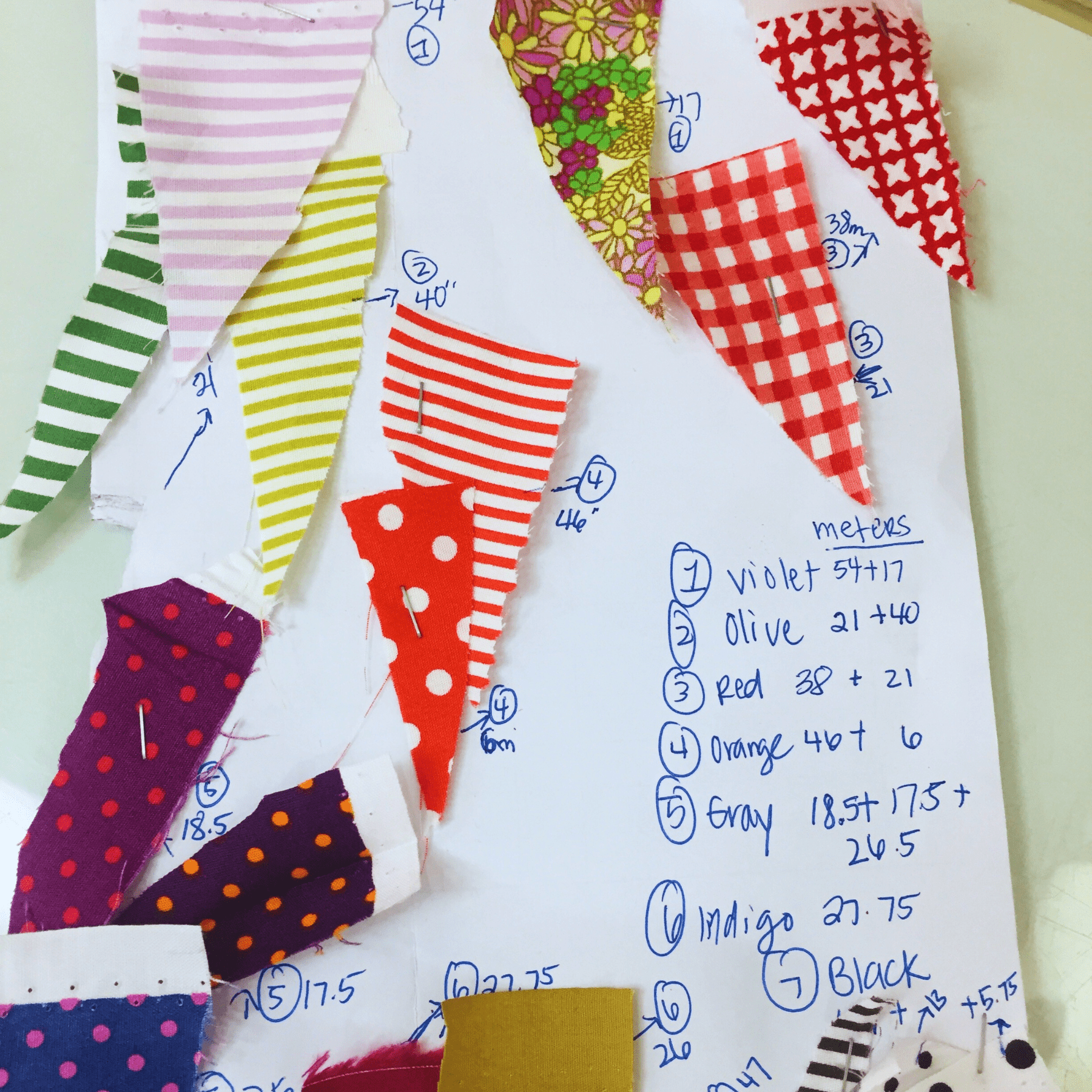

Next, the lining for each bag is cut to size and sewn onto the leather. Each season we select unique deadstock patterns per color of leather. Deadstock is the term applied to overstock fabrics that are no longer needed for their original purpose and would otherwise end up in a landfill. So, it's always different, playful, and colorful, and it is using fabric that would otherwise be discarded.

Brooke scoured the shops in Bangkok to find the best quality, and because we love supporting small, female-owned businesses, these are the women we support.

STEP 7: HARDWARE

Once all the bags are assembled, they are ready to ship! They are all bundled together and sent to Lincoln, Nebraska (fun fact: that’s where we store everything!). Once the bags reach Nebraska our US team gets started on hand applying each piece of Omega hardware. Each one is positioned on its bag, a rod screwed in, and a dot of glue applied to hold it together. And there you go, after months of designing, stitching, assembling and travelling our bags are ready to head to their new homes with you.