Heirloom Bags for the Women Who Raised Us

15 Years of Sapahn: A Reflection on Courage, Growth, and Connection

Travel in Style: The Perfect Buttery Soft Leather Bags for Your Next Trip

Handbag Accessories: Elevate Your Look with These Must-Haves

The Ultimate Guide to Buttery Soft Leather Handbags

The Bags of Fall: Tailgate Edition by Betsy

From Clutches to Crossbodies: The Delicious Evolution of Handbag Trends (and Why We're Obsessed)

From Brunch to Boardroom: Rocking Buttery Soft Leather Bags for Every Vibe

5 Handbag Trends That'll Have You Saying 'I Need That' in 2024

Community: When we support each other, we can achieve remarkable things

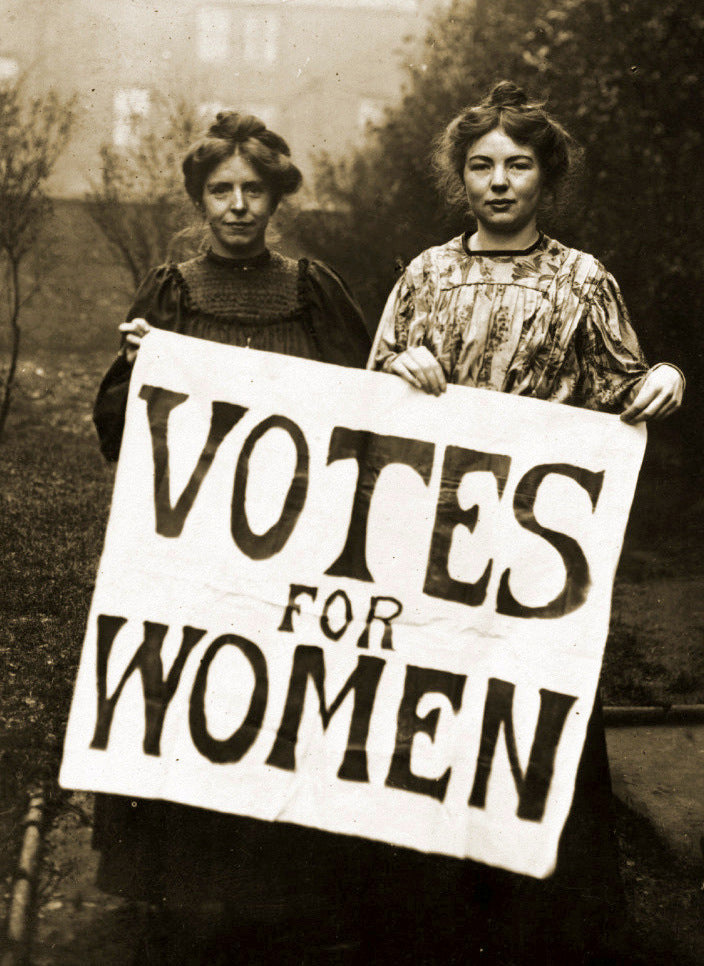

Women's Equality Day: The history and the progress